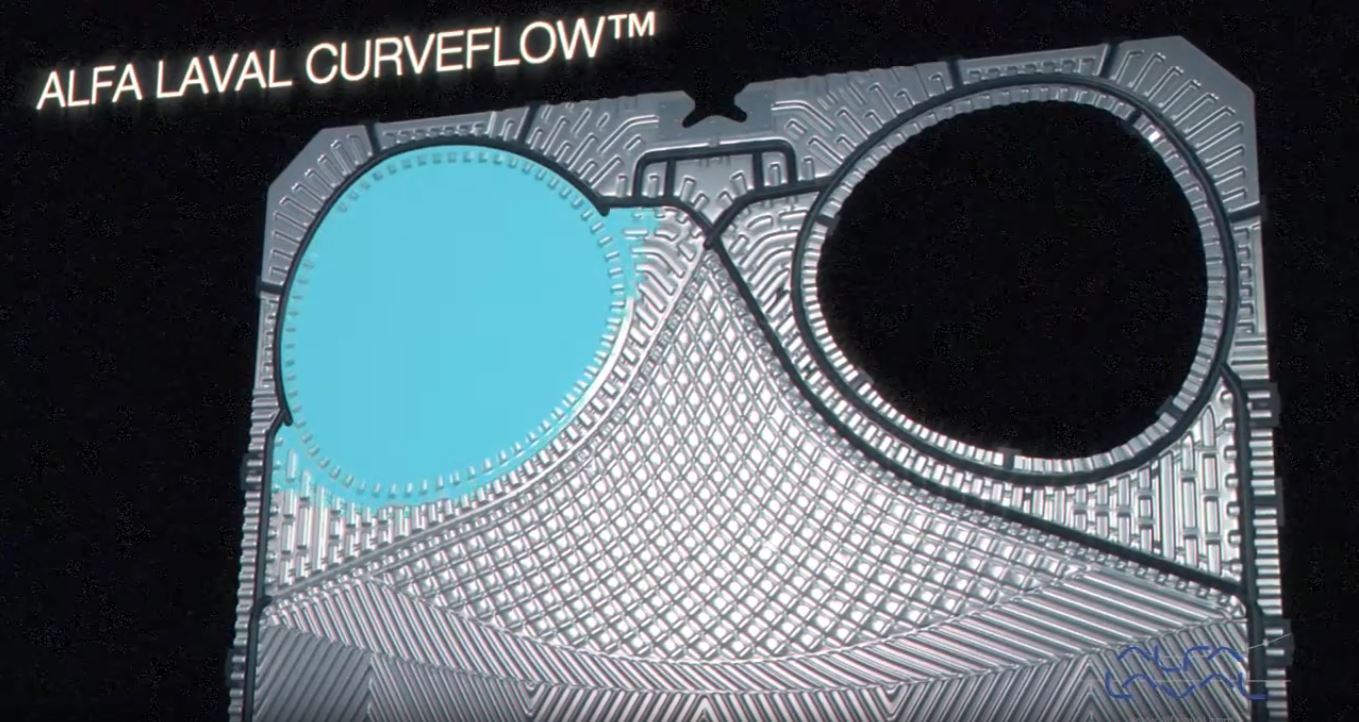

Let’s take a look at evolution of efficiency.

Here's an example of product evolution across AL's hygienic line but we're happy to talk about the evolution of any of the equipment we service and supply. Take process hygiene and product safety to a higher level with the Alfa Laval Hygienic line. This premium range of plate heat exchangers optimizes