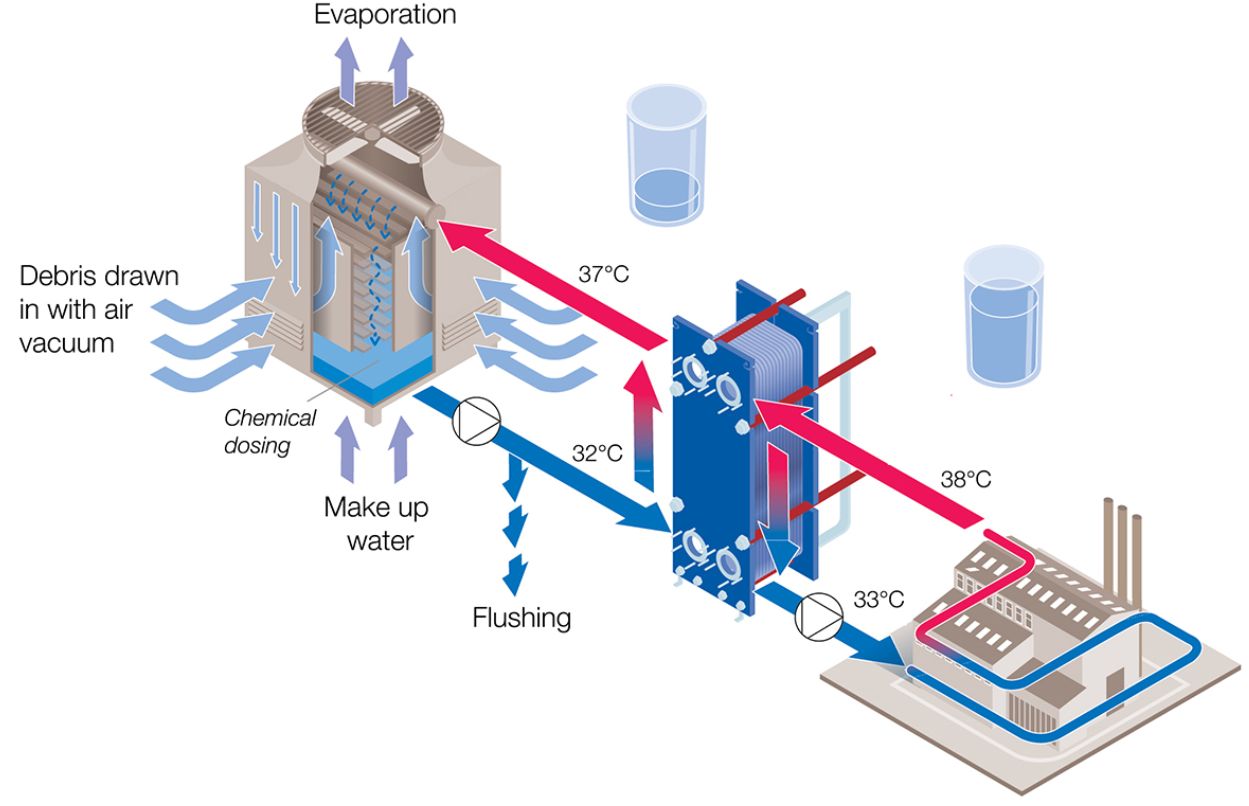

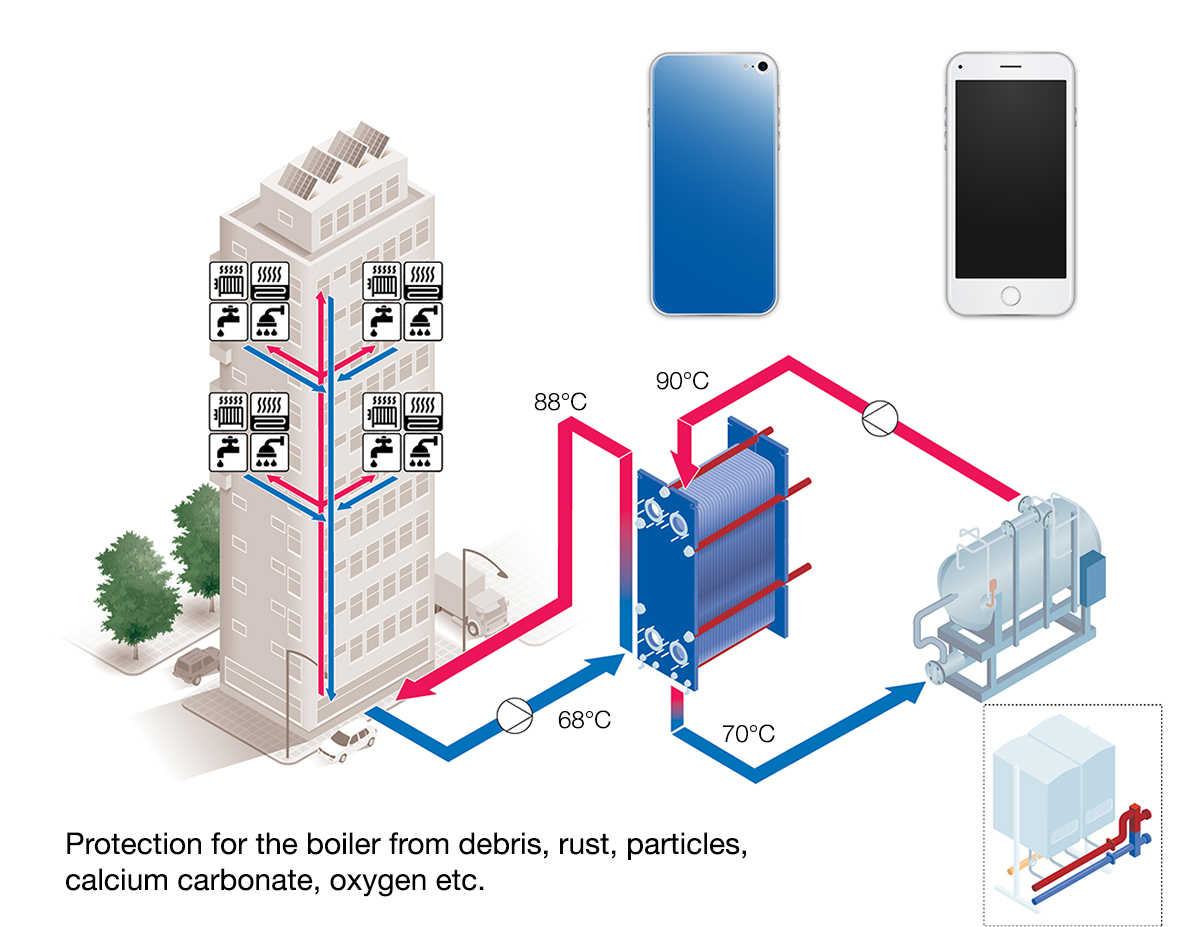

Why install an interchanger?

If you can protect your plant from scale, debris, air borne particles and corrosion, you will save with a greater return on #plantmaintenance and plant longevity. Open cooling towers accumulate minerals such as calcium carbonate and chloride ions which can be harmful to your downstream #coolingplant equipment. In the video below Ismail Uzman from